Patented Thermal Energy Harvesting

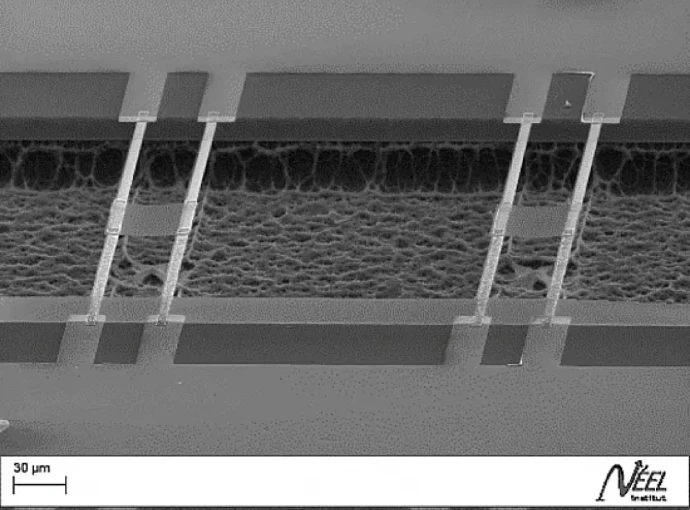

MOÏZ emerged from a fundamental research laboratory in condensed matter physics of the CNRS located in Grenoble, the Néel Institute.

Autonomous Sensors

The technologies used in our autonomous sensors are the result of ten years of work and several research projects funded by Europe, the ANR, the CNRS and the Linksium SATT.

Our autonomous sensors use the thermoelectric effect, and more specifically the Seebeck effect to convert the thermal energy available in their environment into the electrical energy necessary to power them.

The Thermoelectric Effect

The thermoelectric effect is a physical phenomenon describing the conversion of a heat flow into electricity. The best known thermoelectric effects are the Peltier effect, generally used to create cold from an electric current, and the Seebeck effect, which describes the creation of an electric voltage across a material subjected to a temperature difference.

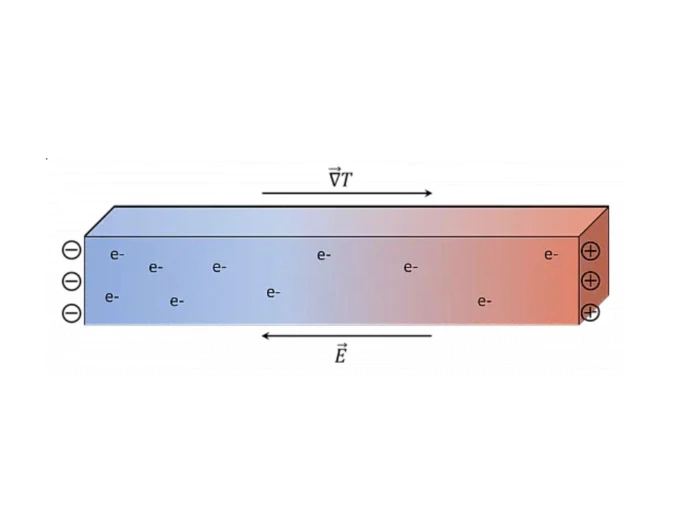

The Seebeck effect is the heart of our autonomous sensors. We can illustrate this effect with the help of the figure representing a metal bar whose ends are subjected to a temperature difference. The hotter electrons are more energetic than the colder ones, their diffusion will be favored, which will result in the appearance of a potential difference at the terminals of the bar.

This effect exists in most of the usual materials but it is more pronounced in some materials called thermoelectric materials. These materials are generally highly doped semiconductor alloys. For example, alloys based on bismuth tellurium are used today in most of the thermoelectric modules marketed around the world.

From the Thermoelectric Effect to the Thermoelectric Module

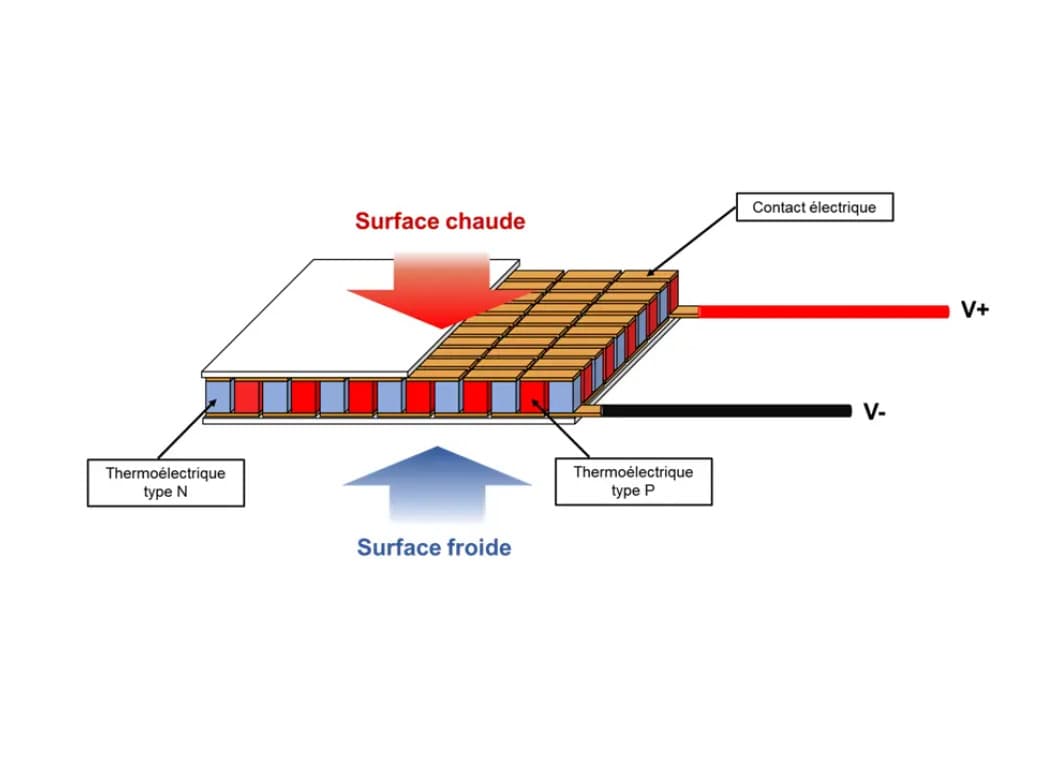

Unfortunately, the conversion efficiency given by the thermoelectric effect does not allow the use of thermoelectric materials as they are. Indeed, voltages produced at the terminals of these materials are of the order of 200 µV.K-1. In order to improve the efficiency of the devices it is necessary to use N and P type semiconductor materials and to connect them electrically in series and thermally in parallel.

The result is a thermoelectric module as shown here. These modules are industrially manufactured, they are essential to cool optical components, especially in telecommunications. The modules used by MOÏZ have been tested in our premises and selected as much for their performances as for their reliability.

A Closer Look

If we take a closer look at the thermodynamic efficiency of the heat-to-electricity conversion, we can see that it only depends on the properties of the thermoelectric materials. Under standard conditions, this efficiency is around 7%. This efficiency is certainly low compared to other energy conversion technologies, but it is more than sufficient to power one or more connected sensors in most industrial environments.

Retaining Efficiency

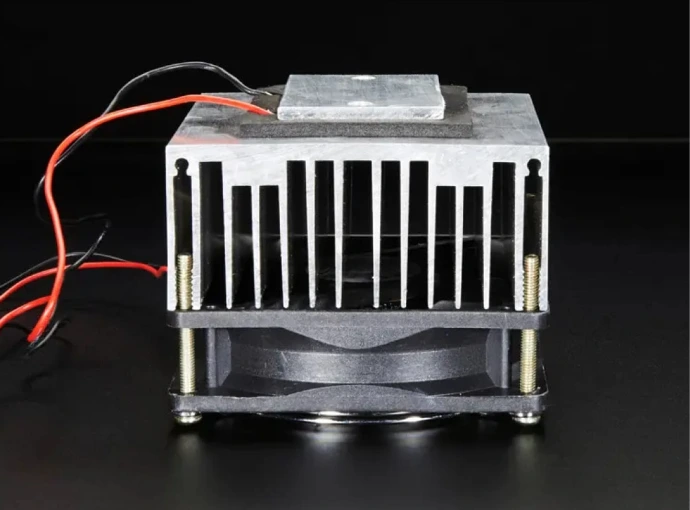

To retain this efficiency, it is necessary to evacuate 93% of the incoming heat flow, otherwise the thermal balance will homogenize the temperatures of the hot and cold sides of the thermoelectric module. The recovered power will then tend towards zero. Consequently, most thermoelectric devices are coupled to large heatsinks, or even fans! The challenge is to properly evacuate the heat from the cold surface.

This is why we take great care in optimizing the thermal design of our autonomous sensors. This optimization has led to the filing of a patent and allows us today to achieve complete autonomy in many industrial environments.

A New Frontier

Thermoelectric Modules on Silicon

In addition to our field-tested technology, MOÏZ is developing novel type of planar thermoelectric nanomodule (nano-TEG) that can be integrated on silicon using MEMS technologies.

The architecture of our patented silicon-based energy harvesting technology offers many advantages over existing Peltier modules on the market:

The membrane-like structure of the nano-TEGs allows for efficient heat removal without the use of heatsinks.

The low mass of the membrane increases the sensitivity of the device to temperature fluctuations.

Conversion can be achieved by any thermoelectric material deposited as thin films.

The use of ultrathin layers allows to reduce the amount of thermoelectric material needed for its operation.

The nano-TEGs have the particularity of being able to be paralleled by hundreds allowing to obtain an impedance of a few ohms despite the use of thin layers. It is this last point that allows our generators to be coupled with frequently used electronic components.

High performance, easily integrated, this energy harvesting solution will be launched in 2028.